denCity is a Masters level research project by Sahra (Peter Sovinc, Saif Almasri, Suryansh Chandra) at the Design Research Lab, Architectural Association, London.

denCity is a critique of modern day urbanization and city planning methodologies that are based on 20-year masterplans of linear city growth and are incapable of dealing with the pace of change of modern economic landscapes, societal conditions and life styles. It researches new interactive systems of master planning and urban design, that are capable of coping with completely different economic scenarios within a matter of seconds, producing relevant FAR and height regulation maps, programmatic distribution information and street networks.

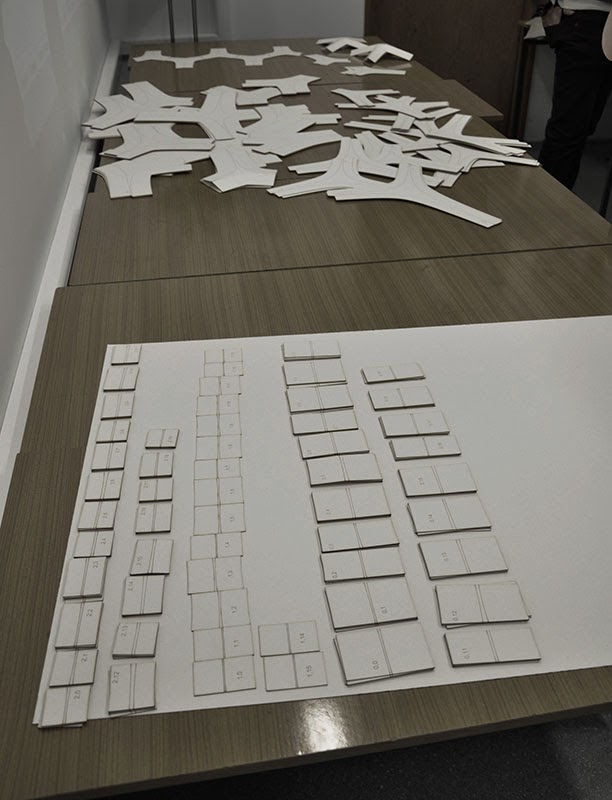

At the architectural scale, denCity critiques modern day urbanization that is shaped by an assumed unending abundance of energy sources and the short sighted reliance on private vehicular transportation. The research is focussed on developing super high density 20 FAR pedestrian ladscapes and addressing issues of natural light penetration and ground association observed in contemporary high density cities.

Below is the online version of the final project with voice over:

Part 1/2

Part 2/2

Please feel free to leave you feedback/suggestions/etc.

denCity is a critique of modern day urbanization and city planning methodologies that are based on 20-year masterplans of linear city growth and are incapable of dealing with the pace of change of modern economic landscapes, societal conditions and life styles. It researches new interactive systems of master planning and urban design, that are capable of coping with completely different economic scenarios within a matter of seconds, producing relevant FAR and height regulation maps, programmatic distribution information and street networks.

At the architectural scale, denCity critiques modern day urbanization that is shaped by an assumed unending abundance of energy sources and the short sighted reliance on private vehicular transportation. The research is focussed on developing super high density 20 FAR pedestrian ladscapes and addressing issues of natural light penetration and ground association observed in contemporary high density cities.

Below is the online version of the final project with voice over:

Part 1/2

Part 2/2

Please feel free to leave you feedback/suggestions/etc.